Packing Materials

Aluminum Blister Foil

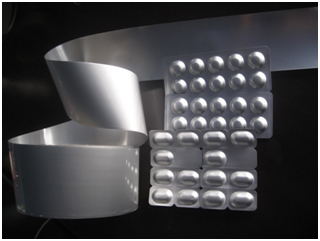

Aluminum Blister Foil

It is globally known that Aluminum Blister Foil is a good barrier to moisture, vapor and gases and it is suitable for high speed packing applications on rotary and flatbed blister packing machines.

The blister packs are compact in size and economical, as compared to strip packs. Tablets can be removed easily from blister packs, as the hard foil breaks quickly when tablet /capsule is pressed from PVC side. We offer both unprinted and printed foil as per customer's requirements with different foil thickness and heat seal lacquer grammage.

It is globally known that Aluminum Blister Foil is a good barrier to moisture, vapor and gases and it is suitable for high speed packing applications on rotary and flatbed blister packing machines.

The blister packs are compact in size and economical, as compared to strip packs. Tablets can be removed easily from blister packs, as the hard foil breaks quickly when tablet /capsule is pressed from PVC side. We offer both unprinted and printed foil as per customer's requirements with different foil thickness and heat seal lacquer grammage.

Standard Specifications of Aluminum Blister Foil (Foil/HSL):

|

Composition of Aluminum Foil: |

||

|

Thickness of Aluminum oil in micron |

20 |

25 |

|

Thickness Tolerance (+/-8%): in mm |

+/- 0.0016 |

+/-0.002 |

|

Al. Foil weight (gsm) |

54 (+/-8%) |

67.5 (+/-8%) |

|

Pinholes in Al. (no/sqm) max |

50 |

35 |

|

Composition of Heat Seal Lacquer (HSL): HSL : Grams per Square mtr (gsm) |

4-6 |

4-6 |

For all Aluminum Foil Thickness:

|

Composition: |

|

|

Aluminum Foil Alloy |

AA 1200 / AA 1235/ AA8011 |

|

Aluminum Foil Finish |

Matt / Bright |

|

Temper (Soft / Hard) |

Hard (Full Hard |

|

HSL Coating Surface |

Matt / Bright |

|

Sealing Strength |

450 grams / 15 mm |

|

Sealing Surface |

Foil to PVC,PVC/PVDC, alu-alu |

|

Dimensions |

|

|

Reel Width : Unprinted |

60 - 900 mm |

|

: Printed |

60-720 mm |

|

Width Tolerance |

+/-0.5 mm |

|

Core Material |

Aluminum /Plastic |

|

Core Diameter |

58/70/76 mm |

|

Reel Diameter /Reel OD |

230-300 mm(standard) |

|

Reel OD Tolerance |

+/-5mm |

|

Type of Joint |

Single Butt / DoubleButt / Lap Joint |

|

Type of Tapeused for Joint |

Paper Tape/ Plastic Tape (Red, Brown or Black colour) |

|

Properties of Printed Side: |

|

|

Colour |

1-5 |

|

Ink Adhesion Test |

No ink lifting |

|

Printing Surface |

Matt / Bright (non HSL side) |

|

Repeat Length Tolerance |

+/- 0.5 mm |

|

Registration Tolerance |

+/-0.5 mm |

|

Printing |

As per design / artwork |

|

Print Primer |

0.25 gsm max |

|

Other |

Abrasion, water and heat resistant |

Recommended Operating Conditions:

Temperature ( deg. C) : 190 deg C Dwell Time : 0.5 seconds (min.)

Remarks:

- All aforementioned specifications are standard specifications. We could offer tailor made specifications as per customer's requirement

- In case of Printed Designs, customers to specify unwinding direction and supply artwork/design of printed designs with colour scheme.

- We could also offer higher (6-8gsm) and lower (3-5gsm) grammage of Heat Seal Lacquer.

- The lacquer used is food/Pharma grade & it is safe for contact with tablets /capsules.

- Normal packing of the product is corrugated cartons/ wooden case/ Pallets..etc. Customer is to specify their packing requirements

|

Structure of Alu-Alu Foil |

25 micron OPA Film/ Adhesive / |

|

45 micron Aluminum foil / 60 micron PVC film |

|

Test Parameter |

Specification Value |

Tolerance Limit |

|

Total Grammage |

240 gsm |

+/-8% (+/-19 GSM) |

|

Total Thickness |

145 micron |

+/-8% (+/-12 micron) |

|

Width |

Customer Specified |

+/-0.5 mm |

|

Core ID |

76 mm |

+/-0.5 mm |

|

Reel OD |

250-350mm |

+/- 5 mm |

|

ECV / Cup Depth |

9 mm |

min. value |

|

Seal Strength with |

500 grams/ 15 mm |

min. value |

Rigid PVC Films

Rigid PVC Films

We offer wide range of high performance calendared rigid PVC film for Pharmaceutical Packaging. These PVC films are manufactured from excellent quality pharmaceutical grade raw materials using latest calendaring technology. These films are also produced under the most rigid quality standards in the industry, meeting all national and international regulations like Pharmacopoeia, FDA requirements, BGA recommendations of German Federal Health Authority, EC (European Community) directives and GMP standards.Product Features:

- Manufactured under controlled environment.

- Full production traceability.

- Meets all International Drug Regulations.

- Controlled shrinkage, consistent forming and punching.

- Superior thermoforming.

- Special grades available for deep drawing.

- Taste and smell neutral.

- Low migration levels.

- Low moisture and gas transmission rates.

- Excellent dimensional stability and salability.

- Guaranteed thickness control for higher yields.

- Available in wide range of colours.

- Good tight winding for trouble free operations.

Applications:

For: Blister Packing of Tablets, Capsules, Syringes, Needles, Ampoules, Vials, Suppository packs, Ointment tubes, Medical Kits, Surgical dressings ..etc

Technical Specification :

|

Thickness |

200 micron to 500 micron |

|

GSM (Grams per square meter) |

200 microns : 276 +/-10% |

|

250 microns : 345 +/-10% |

|

|

300 microns : 414 +/-10% |

|

|

350 microns : 483 +/-10% |

|

|

400 microns : 552 +/-10% |

|

|

500 microns : 690 +/-10% |

|

|

Colours |

Glass clear, Yellow, Red, Amber, Green, Orange, White Opaque & many other shade as per our standard shade card. |

|

Reel Width |

As per your requirement ( +/- 1 mm) |

|

Core ID/ OD |

ID: 76 mm and OD: 400 mm maximum |

|

Packing |

Standard Export Packing |

PVDC Films

PVDC Films

Our PVDC coated PVC film has excellent barrier properties against: moisture, water vapor, UV light, aroma, inorganic acids, alkalies, aqueous salt solutions, organic water soluble acids, aliphatic hydrocarbons, esters of long chain fatty acids, detergent base materials, emulsifying agents and wetting agents.

The product categories preferred to be packed in PVDC coated PVC film are: Antibiotics, Anti Tuberculosis drugs, Vitamins, Calciums and Zinc compounds, Analgesic, Anti-inflammatory and Anti-depressents, Drugs acting on alimentary system, Ayurvedic rejuvenators, Cardiovascular drugs, Enzymes, Antiprotozal, Antihistamines and Sedatives and Hypnotics.

Our PVDC coated PVC film has excellent barrier properties against: moisture, water vapor, UV light, aroma, inorganic acids, alkalies, aqueous salt solutions, organic water soluble acids, aliphatic hydrocarbons, esters of long chain fatty acids, detergent base materials, emulsifying agents and wetting agents.

The product categories preferred to be packed in PVDC coated PVC film are: Antibiotics, Anti Tuberculosis drugs, Vitamins, Calciums and Zinc compounds, Analgesic, Anti-inflammatory and Anti-depressents, Drugs acting on alimentary system, Ayurvedic rejuvenators, Cardiovascular drugs, Enzymes, Antiprotozal, Antihistamines and Sedatives and Hypnotics.

The silent features of our PVDC coated PVC films are per follow:

- Meets all regulatory requirements.

- Produced in fully air conditioned, dust proof plant.

- Excellent oxygen and moisture barrier properties as compared to normal PVC film.

- Good thermo formability PVDC is very cost-effective, as coating weight can be customized depending on the requirements of the barrier properties.

- Medical grade and non-toxic.

- High levels of transparency which improves the aesthetics of the product.

|

250/40 |

250 micron PVC / 40 micron PVDC |

|

250/60 |

250 micron PVC / 60 micron PVDC |

|

250/80 |

250 micron PVC / 80 micron PVDC |

Other structures PVC/ PVDC can be offered on request:

- PVC thickness ranging from 200,250,300 &350 microns.

- PVDC coating ranging from 20 to 90 GSM.

- PVC is available in various colours and in transparent opaque nature

|

Thickness |

200 micron - 350 micron |

|

Options |

Glass Clear or Coloured, Transparent or Opaque. |

|

Coating |

20-90 gsm. |

|

Forming Temperatures |

130-150oC 20-90 gsm. |

|

Width |

50-1200 mm (+/-1 mm) |

|

Core ID |

: 76 mm (+/-1 mm) |

|

Reel OD |

300-400 mm (+/-1 mm) |

|

Standard Export Packing on Pallets |

|

Glass Bottles

Glass Bottles

Highly trained and skilled hands create the accurate dies and mould equipment that are so essential for the high quality of the glass bottles. The production process comprising of raw material mixing, batching, melting, refining of glass and conversion of molten glass into bottles, commenced on a fully automated plant. The silica-soda-lime mix is converted into fully formed and annealed bottles automatically. We are pleased to offer various sizes and shapes of glass bottles to our clients starting from 15ml bottle up to 500ml bottle. Considering the fragile bottles are following proper procedures to ensure safe delivery to our clients.

Highly trained and skilled hands create the accurate dies and mould equipment that are so essential for the high quality of the glass bottles. The production process comprising of raw material mixing, batching, melting, refining of glass and conversion of molten glass into bottles, commenced on a fully automated plant. The silica-soda-lime mix is converted into fully formed and annealed bottles automatically. We are pleased to offer various sizes and shapes of glass bottles to our clients starting from 15ml bottle up to 500ml bottle. Considering the fragile bottles are following proper procedures to ensure safe delivery to our clients.